| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | FUSHUN |

| Model Number : | Inconel 718 |

| Certification : | ISO 9001 |

| Delivery Time : | 20 DAYS |

| Payment Terms : | TT LC DP |

| Supply Ability : | 3000 TONS PER YEAR |

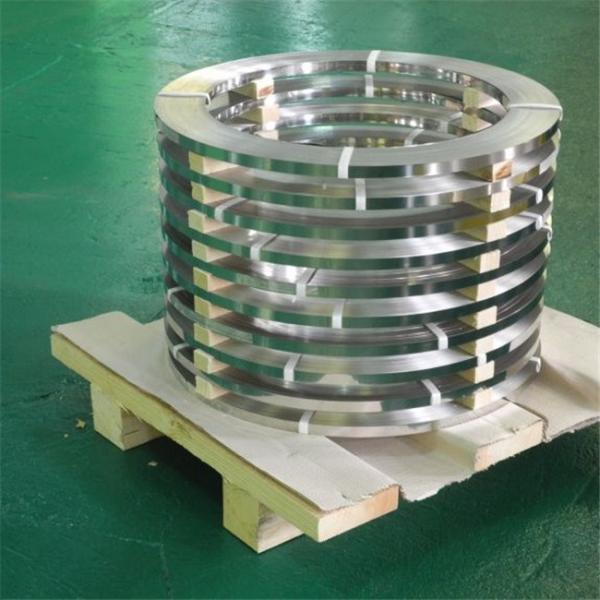

Delivery condition: cold-rolled, heat-treated and pickled or bright-annealed

Thickness mm (in): 0,025-3 (0.001-0.12)

Width mm (in): 4-750 (0.16-29.5)

Rolled sheet – separated from the coil – are available in lengths from 250 - 4,000 mm (9.84-157.48 in).

Inconel 718 is an age-hardenable Alloy-chromium alloy that combines corrosion resistance with high strength and good fabricability. It has high creep-rupture strength at temperatures up to 700 ℃. Its excellent relaxation resistance contributes to its application in springs.

The alloy is used in jet engine and high-speed airframe parts such as wheels, buckets and spacers, and high-temperature bolts and fasteners. Inconel 718 is also used in the oil and gas drilling and production industries due to its high strength and resistance to chlorides, stress corrosion and sulfide stress cracking. Within these industries the alloy has been used for valves, pump shafts and wellhead components.

718 Sheet, Coil and Plate: UNS N07718, AMS 5596, ASTM B 670, ASME SB 670, B50TF14,

718 Round Bar: UNS N07718, AMS 5662, ASTM B 637, B50TF15, B50809D (Power Generation)

other:AMS 5662, AMS 5663, AMS 5832, AMS 5962, ASTM B637, GE B14H89, ISO 15156-3, (NACE MR 0175)

Good creep rupture strength at high temperatures

Higher strength than Inconel X-750

Better mechanical properties at lower temperatures than Nimonic 90 & Inconel X-750

Age hardenable

High temperature dynamic applications

| Ni | Fe | Cr | Cu | Mo | Nb | C | Mn | P | S | Si | Ti | Al | Co | B |

| 50.00-55.00 | Remainder | 17.00-21.00 | .30 max | 2.80-3.30 | 4.75-5.50 | .08 max | .35 max | .015 max | .015 max | .35 max | .65-1.15 | .20-.80 | 1.00 max | .006 max |

| Condition | Approx. tensile strength | Approx. operating temperature depending on load^^ and environment | ||

| N/mm² | ksi | °C | °F | |

| Annealed | 800 – 1000 | 116 – 145 | – | – |

| No 1 Temper | 1000 – 1200 | 145 – 175 | – | – |

| Spring Temper | 1250 – 1500 | 180 – 225 | – | – |

| No 1 Temper + Annealed + Aged | 1250 – 1450 | 181 – 210 | -200 to +550 | -330 to +1020 |

| No 1 Temper + Aged | 1520 – 1720 | 220 – 250 | Contact Us | |

| Spring Temper + Annealed + Aged | 1250 – 1450 | 181 – 210 | -200 to +550 | -330 to +1020 |

| Spring Temper + Aged | 1700 – 1950 | 247 – 283 | Contact Us | |

Heat treatments may be adjusted to give required properties. For the best combination of tensile and stress rupture properties, the following quite complex cycle is recommended :

1 hr at 1750/1800ºF (955/980ºC) and air cool, then 8 hrs at 1325ºF (720ºC) and cool at 100ºF/hr (56ºC/hr) to 1150ºF (620ºC), hold for 8 hrs and air cool.

For the best room temperature and cryogenic tensile properties, the cycle is :

1-2hrs at 1950ºF (1065ºC) and air cool, then 8 hrs at 1325ºF (720ºC) and cool at 100ºF/hr (56ºC/hr) to 1150ºF (620ºC), hold for 8 hrs and air cool.

Because of its strength, INCONEL alloy 718 is more resistant than most materials to deformation during hot forming. It is readily hot-worked if sufficiently powerful equipment is used. Hot forming is performed in the 1650°-2050°F temperature range. In the last operation, the metal should be worked uniformly with a gradually decreasing temperature, finishing with some light reduction in the 1650°-1750°F range. This procedure is necessary to ensure notch ductility in stress-rupture applications when material has been annealed and aged.

INCONEL alloy 718 can be cold-formed by standard procedures used for steel and stainless steel.

INCONEL alloy 718 can be readily machined, but its high strength and work-hardening characteristics must be considered in the selection and use of proper tool materials and design, operating speeds, and coolants. When machined in the age-hardened condition the alloy will have a slightly better finish; chip action on chipbreaker tools will be better. The use of annealed material, however, provides easier machining and longer tool life.

This alloy, designated INCONEL alloy 718SPF, is available as annealed sheet in thicknesses from 0.02 to 0.08 inches (0.5 to 2.0 mm) in widths up to 36 inches (914 mm). The specification SAE AMS 5950 was developed to define the requirements for the alloy.

|